TIG Welding for Beginners: 14 Tips & Tricks to Get You Started

TIG welding is a form of welding that uses a tungsten electrode to join metals. It’s the best welding process for thin-walled metal such as jewelry. It’s an excellent alternative to other welding processes such as gas metal arc welding (GMAW) because it provides a smoother weld with less porosity.

That said, TIG welding can be a tricky skill to master, but with enough practice, you can produce top-notch welds that your friends and family will be proud of.

In this article, we will look at easy TIG welding tips and tricks to help you on your path to becoming a professional welder!

TIG Welding for Beginners: 14 Tips & Tricks to Get You Started

The 14 TIG Welding Tips & Tricks to Get You Started

1. Select the Correct Tungsten

Tungsten comes in several different sizes and shapes. There are many variables to consider when selecting a suitable one for your welding project.

If you’re using an AC/DC machine, use DC tungsten. It can handle higher currents than AC ones. Also, avoid using high-frequency (HF) tungsten if you’re using an inverter-style machine. It’ll damage the tungsten electrode.

Usually, red tungsten is used for steel, while green tungsten is for aluminum. Try traditional electrodes first before deciding on the tungsten electrode you’ll use.

Consult with your equipment manufacturer or distributor before purchasing any tungsten electrodes. They may have some recommendations based on your setup and needs.

2. Ensure that Everything is Clean

It may seem obvious, but ensuring the work area is clean and contamination-free will help prevent problems later. It means removing dirt, grease, oil, and other contaminants from the surface of the materials you’re welding.

Use a wire brush or scouring pad to remove any loose material before starting your welding project. It’s worth investing in some cleaning products specifically designed for TIG welding.

Additionally, ensure you also clean your base metal and rod using a degreaser. Then, scrub it using a wire brush. Don’t use the same brush on different metals.

3. Don’t Melt the Filler Rod Directly

Many people assume that if you want to melt a filler rod, you should hold it directly against the puddle created by the tungsten electrode. But this isn’t recommended as it can damage your tungsten electrode tip and even create unwanted porosity in your weld bead. It also makes your weld weaker.

Hold the filler rod several inches away from where you’re working on each pass until there is enough heat. Remember that the torch melts the base metal, while the molten puddle melts the filler material.

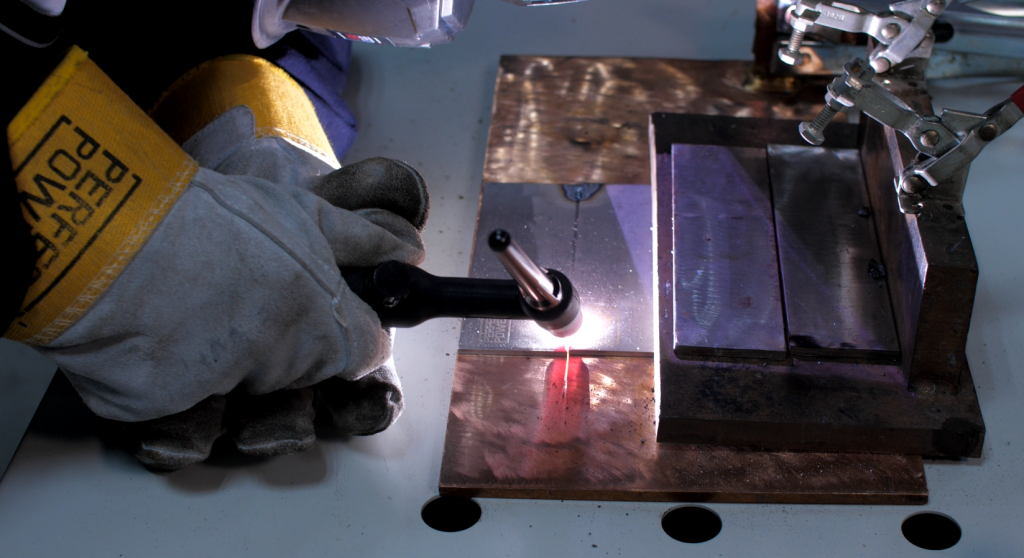

4. Always Wear Protective Gear When TIG Welding

TIG welding involves using an electrode made of tungsten or carbide. It heats up when electricity passes through it. The heat melts the base metal you’re welding together, creating a bond between two pieces of metal.

This process can generate sparks that can become embedded in your skin or clothing. So, always wear protective gear. Personal Protective Equipment (PPE) includes heat-resistant welding gloves, a helmet with eye protection, and a heat-resistant welder’s jacket.

Also, you need lung protection or a welding respirator to protect your lungs from the welding gasses. Ear plugs or muffs and welding boots are crucial, too.

5. Grind Your Tungsten Well

One crucial part of TIG welding is grinding your tungsten well lengthwise and making it as even as possible. This means making sure that there are no sharp edges or burrs on the end of your tungsten; these can cause porosity and other problems in your finished welds. The grinding wheel also wears out fast if you don’t do it right.

Grinding the tungsten opposite or incorrectly can produce an unstable arc. You need a tungsten sharpener or a bench grinder to grind tungsten.

6. Use Minimum Power When TIG Welding

When you first start with TIG welding, it can be tempting to crank up the power on your welder so that you can make your weld fast. But this is not recommended because it causes more spatters. Spatter leads to poor-quality welds or even makes the weld burn through.

So, use a lower power setting you can handle. Also, ensure you have learned better techniques for achieving good results with fewer spatters.

The best way to learn how much power you need on your TIG welder is by practicing different techniques on scrap metal. This way, you’ll find what works best for your material and process.

7. Use a Suitable Shielding Gas

As a beginner welder, the first thing you should do in TIG welding is to ensure your shielding gas is suitable for TIG welding. The shielding gas protects the molten metal from oxygen, nitrogen, and hydrogen in the air.

It ensures that the molten metal doesn’t burn up before solidifying on the metal surface. If there are too many of these gasses in the atmosphere, it can cause oxidation or even fire!

So, choose a shielding gas that contains 100% argon or a mixture of argon and helium. A shielding gas protects your weld puddle from oxygen, hydrogen, and nitrogen during its cooling phase.

The cooling phase is when you stop feeding wire into the torch tip and when your weld cools down. Also, don’t use helium alone as a shielding gas. It can make it challenging to TIG weld. Adjust the shielding gas between 15 and 20 cubic feet per hour to weld safely.

8. Maintain the Torch Angle and the Rod

The torch angle is a crucial factor if you want to get an excellent weld with the TIG welding technique. It determines how much heat you’ll apply to the base material and how much penetration you get in your weld.

Always keep your palm on top of the electrode to maintain a consistent torch angle and keep it in place while welding and prevent it from sliding down the tungsten tip.

Another alternative is keeping the torch angle at 20º or less. Also, ensure you feed the rod into the welding pool. If you don’t do all these, the rod may begin melting before it gets to the welding pool.

9. Choose Larger Rods When TIG Welding

When you are TIG welding, you will notice that many different sizes of tungsten rods are available. Some people think smaller rods produce better results than larger ones, but this isn’t true! Larger rods will give you better results than smaller ones. These are mostly used on farm machinery or heavy equipment.

A larger rod is easier to feed with and it produces less spatter and slag build-up in the puddle. It makes it easier to see what’s happening inside your weld puddle.

As a beginner in TIG welding, start with 1/16 to 1/8 inches rods. Usually, ordinary TIG welding rods have a diameter of 1/16 or 3/32 inches. Always use thinner welding rods for thin metals and thicker rods for thick metals.

10. Reduce the Arc Steadily

You need a foot paddle to regulate the current flow through the welding rod. It helps you produce the heat you need for TIG welding. It also gives you more freedom of movement when welding. You don’t have to always keep both hands on the torch. This allows for more precision in forming a bead and gives you better control over its shape.

The foot paddle also allows you to release the arc steadily. It means that you should not try to go from a large to a small arc immediately.

Instead, work your way down slowly, allowing the weld pool to shrink. Shutting down suddenly may cause cracking. Ensure the foot paddle is around ¾ of the way down.

11. TIG Welding Needs the Utmost Concentration

If you’re new to TIG welding, you’ll find that concentration is a crucial factor when producing a high-quality weld. Always focus on your workpiece.

You must be careful when making your welds and take time to keep the arc stable. That’s the only way to ensure that your welds go where they should. The slightest distraction could cause an incomplete arc and result in poor welds.

Also, there are high chances of burn-through or porosity in your welds. That’s why it’s recommended that beginners attempt TIG welding only under supervision. Afterward, they can perform TIG welding on their own once they develop an instinct for how long each weld will take.

12. Ensure You’re Welding in a Well-Ventilated Workplace

TIG welding is a safe process, but it produces fumes. So, it’s crucial to work in a well-ventilated area. Set up your TIG welding station outside or near an open window if possible. This way, any fumes produced can escape from the area fast and easily.

Ventilated workplaces help circulate fresh air, lessening the toxicity of welding fumes to the TIG welder.

13. Find Ways to Support Your Hands

TIG welding is more delicate than other types of welding. It needs more finesse. One thing that makes it challenging is that you need to hold your torch with one hand and manipulate the rod with the other hand.

If you’re just starting with TIG welding, your hands aren’t used to holding onto a metal rod while trying not to get burned by sparks flying everywhere. It can be challenging if you don’t have a good way to support both hands.

Firm support for your hands will enable you to move the TIG welding torch accurately.

14. Clean a Contaminated Tungsten Electrode Instantly

One of the most common problems with tungsten electrodes is contamination. It happens when you leave your tungsten electrode in contact with the base metal for too long.

The tungsten electrode can also get contaminated with bits of slag, rust, or foreign material that can affect your weld quality. Using a wire brush or a bench grinder, grind away any remaining scratches on the surface of the tungsten electrode. Then, wipe it with acetone.

Alternatively, you can replace a contaminated tungsten electrode. As you begin TIG welding, you should have a couple of pre-sharpened tungsten electrodes on your working table or bench.

Conclusion

TIG welding is a craft that takes both persistence and patience. The process of creating quality welds can be lengthy. It involves using several tools compared to other types of welding.

If you’re a beginner TIG welder, these tips and tricks will allow you to take on basic TIG welding jobs and do them to perfection. Remember to practice and don’t be afraid to try new things.