TIG Welding Aluminum: A Comprehensive Guide

TIG welding, also known as Gas Tungsten Arc Welding (GTAW), is a highly versatile welding process that is widely used for welding a variety of metals, including aluminum. TIG welding is considered one of the best welding processes for welding aluminum due to its precision and ability to produce high-quality welds. Here’s a comprehensive guide to TIG welding aluminum.

- Equipment TIG welding aluminum requires specific equipment, including a TIG welder, a TIG torch, a filler rod, and a shielding gas. The TIG welder is the main power source, while the TIG torch is used to heat the metal and create the weld. The filler rod is used to add material to the weld, and the shielding gas is used to protect the weld from oxidation and contamination.

- Preparation Before welding aluminum, it’s important to prepare the metal by cleaning it thoroughly and removing any surface contaminants such as oil, grease, or paint. This can be done by using a degreaser, sandpaper, or a wire brush. The metal should also be free of any dents or defects that can affect the quality of the weld.

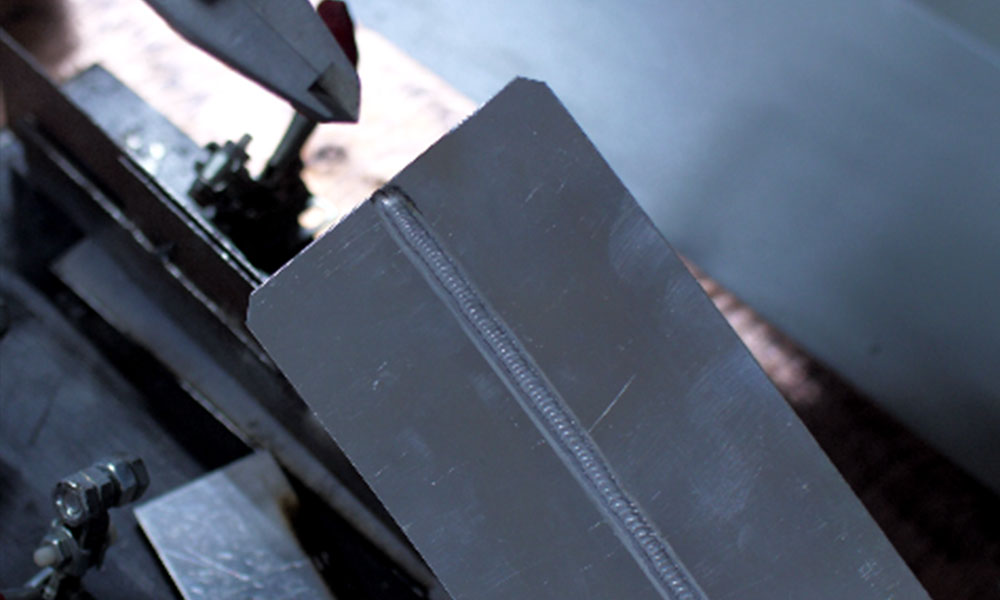

- Welding Techniques TIG welding aluminum requires a slow and steady hand, as well as the proper technique to produce high-quality welds. The TIG torch is held in one hand, while the filler rod is held in the other hand. The TIG torch is used to heat the metal and create the weld, while the filler rod is added to the weld to build up the metal.

- Welding Speed TIG welding aluminum requires a slow welding speed to prevent the metal from overheating and causing porosity in the weld. A slow welding speed also allows the welder to better control the heat input, ensuring a consistent and high-quality weld.

- Shielding Gas The shielding gas is an important component in TIG welding aluminum. Argon is the most commonly used shielding gas for TIG welding aluminum, as it provides a clean and consistent shield that prevents oxidation and contamination of the weld.

- Welding Filler Rod The welding filler rod is also an important component in TIG welding aluminum. A filler rod made of aluminum, such as 4043 or 5356, should be used for welding aluminum, as these rods are specifically designed for this type of metal.

In conclusion, TIG welding aluminum is a highly precise and versatile welding process that is ideal for welding aluminum due to its ability to produce high-quality welds. By using the proper equipment, preparing the metal, using the correct technique, welding at the proper speed, using the correct shielding gas, and using the proper filler rod, TIG welding aluminum can be a safe and effective way to join aluminum components.We recommend this professional TIG Welder:TIG-315PW AC DC IGBT Inverter TIG AC DC Welding Machine